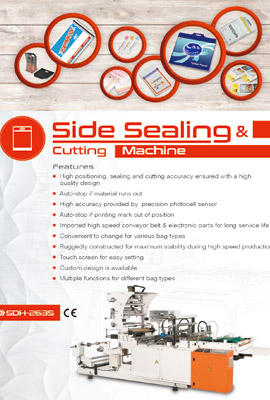

Baby Diaper Bag Making Machine SDH-263SF(NC)

-

Product features

- - Precision cutting control provided by servo motor device.

- - The side sealing bag making machine with automatic folding bag device have auto stop function if polythene material runs out.

- - High accuracy of pivot points tracing provided by high precision photocell sensor.

- - Auto stop if the printing mark out of the right position.

- - Imported >high speed conveyor belt & electronic parts for longer life of the bag on roll device.

- - Convenient to change for various shapes and sizes of bag.

- - Ruggedly constructed for maximum stability during high speed operation.

- - This machinery model can be customized manufacturing into a napper or napkin bag making machine for PP, OPP, CPP, LDPE, HDPE poly material on napkin bags, toliet paper bags, laundry bags and related hygiene outside packaging bags manufacturung.

Optional equipment- - Round hole punching device.

- - Butterfly (Euro hole) puncher.

- - Auto conveyor table.

- - Advanced Edge positioning controller(EPC).

- - Adnavced Heating line device.

- - Vertical continuous seal device.

- - Poly Bag dividing device.

- - Glue applicator.

- - Glue skip.

- - Ultrasonic longitudinal seal device.

- - In line triangle V-type folding device.

- - Auto Hanger insert device.

- - Related equipment required for poly mailer machine.

Leading Customized Side Sealing Bag Making Machine Manufacturer

S-DAI industrial company is one of the global poly baby diaper bag making machine manufacturers and suppliers in Taiwan, mainly providing customized napper, napkin, toliet, laundry and related plastic material hygiene bag making machinery for single layer and powered by advanced servo control unit to many countries, such as China, Philippines, Malaysia, Indonesia, India, Pakistan, Bangladesh, Thailand, Vietnam, Turkey, Saudi Arabia and United Arab Emirates in Asia. In recent years, we not only provide patch handle plastic bag producing machines to Asia, but also provide the heat side seal or bottom seal machine model with wicketer to United Sates(USA), Canada, Mexico, Argentina, Ecuador, Colombia, Guatemala, Belize, Dominican Republic, El Salvador, Panama, Peru and Chile in Amerca. We have deep confidence in the machines produced by our factory because all finished side sealing plastic bags produced by the machines can withstand strength and tensile tests, and their quality has been recognized by the United States and many European countries.

With Many Years of Experience in Customized Manufacturing Bag Making Machine

Base on over 40 years experience on manufacturing fully automatic polythene side seal & bottom seal bag machine, poly mailer machine plastic T shirt bag machine and other auxiliary in production line, S-DAI could procude a highly customized poly hygiene related bag maker machine available for custom film thickness, bag width, bag length or single type drawstring hygiene bag manufacturing in a accurate and easy way. Welcome to visit the "Contact Us" page and fill the form to tell us your customizd specifications. We have rich experience in the design of customized plastic bag manufacturing machines with special specifications. We can set up holes for air ventilation in plastic bags for diaper or toilet paper packaging, so that the bag, air and packaging can maintain the best balance among each other. On an issue that must be mentioned seriously, if you see designed pictures of our company's machinery on the PRM Taiwan or Polaris website, those pictures are not legally authorized. Please mainly refer to the information on this website. You can get high-end mechanical specifications at an affordable cost. This machine is equipped with a digital control panel, allowing you to grasp all important numbers and data when the machine is running through a clear digital interface.

Over 40 years Experience on Customized Baby Diaper Bag Making Machine

Based on more than 40 years of plastic bag maker machine manufacturing experience, we have become the world leader in customized poly bag making machines that could provide the highest strength hot side seal quality, custom & precise punch, quick & stable material feeding device, and high speed production ability on manufacturing poly garbage bags, courier bags, T shirt bags, shopping bags, carry bags. From 2010, we also start to find and open up the high speed napper bag manufacturing machinery markets in Eastern Europe and Africa, providing the cistomized manufacturung services on the fully automatic plastic bag manufacturing machine production line with advanced feeding, folding and rewinder system to many other countries in Europe and Africa, such as Russia, Ukraine, Poland, Lithuania, Hungary, Romania, Bulgaria, Serbia, Croatia, Slovenia, Czech, Slovakia, Greece, France, Germany, Spain, UK, Portgaul, Egypt, Nigeria, Ghana, Kenya, Algeria, South Africa. In addition to advanced side seal and bottom seal device manufacturing capabilities, we also can manufacture a reinforced patch film sealing unit for the polythene bags production line for you at a affordable price. SDH-263SF(NC) is a multifunction system machine model of auto side sealing and cutting, bottom sealing and bag folding powered by advanced servo motors control on our products category, and can also be integrated with packing and printing optional equipment. From min component details to maxi overall production line planning, we provide you with highly customized manufacturing services.

-

Model SDH-263SF(NC) Available Material PP, OPP, CPP, LDPE, HDPE Width of Bag 50 - 600 mm Length of Bag Max.600 mm Speed pc minute

(Depends on material, bag type and size)Max. 200 Thickness

(Depends on material type)0.015~0.08 mm Heater 2 kW Motor 1.5 HP Power Required 5.5 kW Packing Dimensions

(L×W×H)310 × 145 × 205 cm Weight N.W.: 1220 kg

G.W.: 1520 kg

*Specifications are subject to change without notice.*The sealing & folding combo machine line with servo system the machinery model number will with (NC)

-

.jpg)